TM 32-5985-342-14&P

CHAPTER 7

DIRECT SUPPORT MAINTENANCE INSTRUCTIONS

Section I. GENERAL

the Maintenance Allocation Chart (MAC), Appendix D,

7-1 SCOPE OF MAINTENANCE. This chapter contains

and in the Repair Parts and Special Tools List (RPSTL),

instructions for direct support maintenance of the

Antenna Tower TS-9A. Direct support maintenance

includes repair and replacement of those items listed in

Section II. TOOLS AND EQUIPMENT

Allocation chart (MAC), Appendix D. Use of these items

7-2 TOOLS AND TEST EQUIPMENT. The tools and

is listed in table 7-1 below.

test equipment required and authorized for direct

support maintenance are listed in the Maintenance

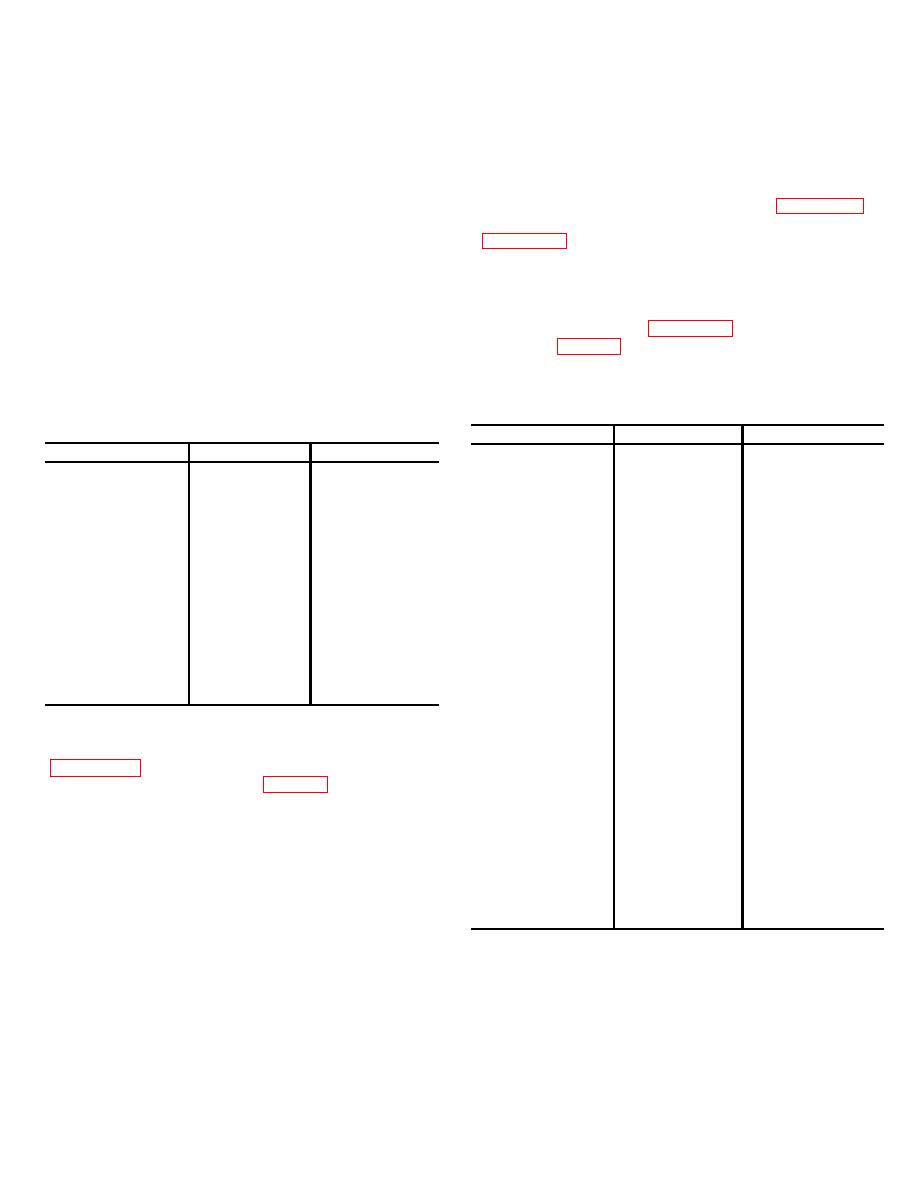

Table 7-1. Direct Support Maintenance Tools and

Table 7-2. Direct Support Maintenance Materials

Test Equipment

NSN

Item

Use

NSN

Item

Use

Trichloroethane

Clean metal parts.

Torque wrench,

Tighten fastener

Brush, bristle

Remove corrosion

0-200 ft-lbs

hardware.

and other foreign

matter from

Torque wrench,

Tighten fastener

metal parts.

0-600 ft-lbs

hardware.

Paint, primer,

Prime coat bare

Allen wrench,

Remove and/or

zinc-chromate

metal parts.

3/8-inch

tighten socket

head bolts.

Paint, enamel,

Finish coat

lusterless, olive

metal parts.

Perform voltage

drab

AN/USM-223

and resistance

measurements.

Brush, paint,

Repainting and

flat, 1-inch-wide

touchup.

7-3 MATERIALS.

The materials required and

authorized for direct support maintenance are listed in

Cheesecloth,

Clean metal

lint-free

parts.

Use of the materials is listed in table 7-2 below.

Oil, lubricating,

Lubricate bear-

30 Wt

ings and bushings.

Grease

Lubricate pawls,

shafts,

bear-

ings, and cam

followers.

Section III. TROUBLESHOOTING

7-4 Refer to Chapter 5, Organizational Maintenance Instructions, Section V, of this manual for troubleshooting

procedures.

7-1

Previous Page

Previous Page