TM 11-5821-284-34

ing the mating connector attached to J2 and rocking the

moisture seal.

a. Carefully slide the coupler into the radome.

assembly. If a screw driver is used to loosen the coupler

assembly, the gasket may be damaged.

Make sure that the spring at the top of variable capacitor

is not damaged.

3-8.

Reassembly of Coupler Assembly A1 and

b. Make sure that all 14 holes are aligned

Radome Assembly A2.

when the coupler and radome assemblies are together.

(fig. 6-5)

Secure the assemblies with the fourteen (14) screws

NOTE

H14.

Be sure that the coupler

gasket is properly in

place to insure a good

Section IV. DIRECT SUPPORT TESTING PROCEDURES

Tests must be performed in an area free of externally

3-9.

General

generated RF fields (no nearby antennas or transmitting

a. Testing Procedures. Testing procedures

sources). Tests must be performed outdoors, away from

are prepared for use by direct support personnel to

nearby metal structures, or in a very large room with no

determine acceptability of repaired signal equipment.

nearby metallic obstructions.

These procedures set forth requirements that repaired

NOTE

signal equipment must meet before it is returned to the

When testing antenna

using organization. The testing procedures may also be

model 437S-1B, replace

used as a guide for the testing of equipment during

R9 on circuit board Al

troubleshooting procedures.

A summary of the

with

a

5600-ohm

performance standards is given in paragraphs 3-11

resistor or connect a

b. Test Instructions.

6850-ohmresistor

in

Comply with the

parallel

with

A1R9.

instructions preceding the body of the chart before

Remove resistor when

proceeding to the tests. Perform each test in sequence.

testing is complete.

Do not vary the sequence. For each step, perform all the

actions required in the test equipment control setting

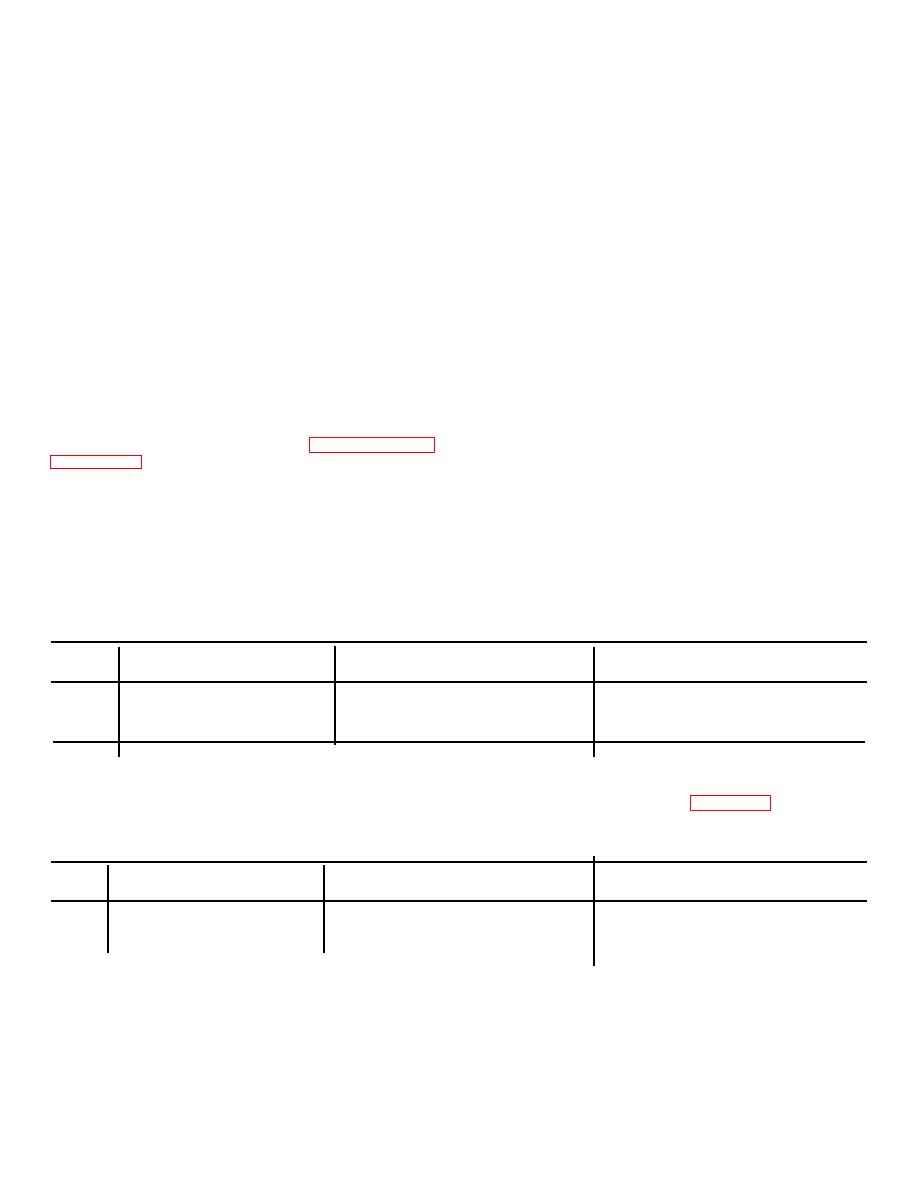

3-11. Physical Tests and Inspection

column; then perform each specific test procedure and

a. Test Equipment and Materials. None.

verify it against its performance standard. If an antenna

b. Test Connections and Conditions. None.

is below standard on any test, refer to the

c. Procedure.

troubleshooting chart in section II.

3-10. Special Requirements

Step

Test equipment

no.

control settings

Test procedure

Performance standard

1

N/A

Inspect radome for cracks, chips,

Radome should be free of cracks,

and breaks.

chips, or breaks.

2

N/A

Inspect coupler for loose or missing

Screws are tight; none missing.

screws.

(4) Power Supply.

3-12.

Antenna VSWR Test

b. Test Connections and Conditions. Connect

a. Test Equipment and Material.

The equipment as shown in figure 3-1 with ground

(1) Test Set, Antenna AN/ARM-115.

plane. Turn on the equipment and allow 5-minute

(2) Maintenance Kit MK-1035/ARC-131.

warmup before proceeding.

(3) Receiver-transmitter RT-823/ARC-131.

Step

Test equipment

no.

control settings

Test procedure

Performance standard

1

AN/ARM-115:

Measure forward and reflected

Reflected power is less than 25% of

METER FUNCTION:

power at 30 MHz. Divide reflected

forward power.

FWD on 10-W SCALE.

power by forward power and

3-3

Previous Page

Previous Page