TM 11-5985-362-13

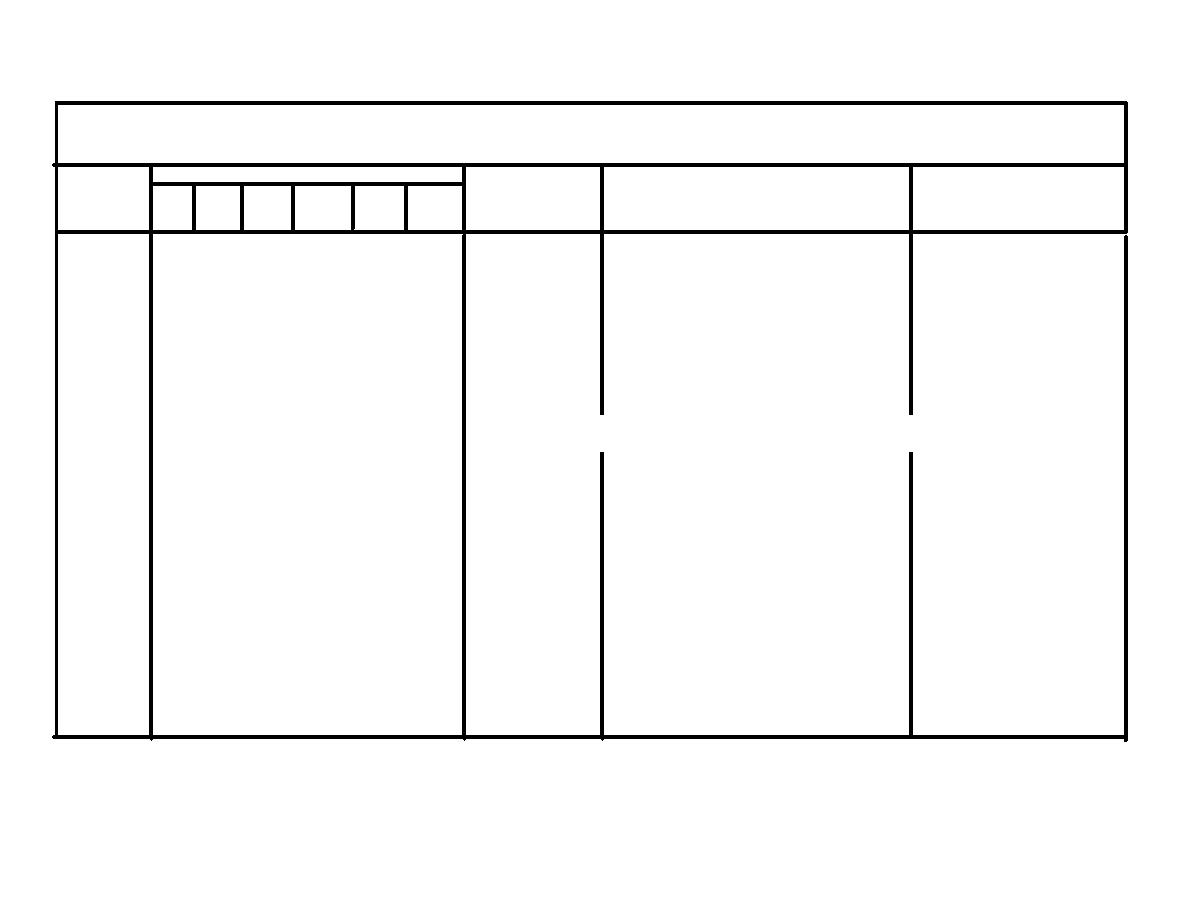

Table 2-1. OPERATOR/CREW PREVENTIVE MAINTENANCE CHECKS AND SERVICES

B-BEFORE INSTALLATION

W-WEEKLY DURING OPERATION

S-SEMIANNUALLY

D-DAILY DURING OPERATION

M-MONTHLY DURING OPERATION

A-AFTER REMOVAL

ITEM

INTERVAL

ITEM TO BE

PROCEDURES

EQUIPMENT IS NOT

NO.

B

D

A

W

M

S

INSPECTED

CHECK FOR AND HAVE REPAIRED

READY/AVAILABLE

OR ADJUSTED AS NECESSARY

IF:

1

1

Tower Light Assy

Visually check operation each night. Schedule

maintenance when and if one of the two bulbs

are out.

2

Tower Guys and

Verify for correct tension. tower vertical, Guys

Catenaries

TAUT.

3

Retension is required.

Visually inspect for broken condition. Schedule

One or more broken insulations.

tSchedule maintenance if required.

WARNING

Transmitter must be shut down and tagged "Out of Service"

4

Antenna Coupler

Visually check weekly and immediately after

electrical storm for signs of arcing damage. Clean

with a soft cloth if required.

5

Tower Winch

Apply four to five drops VV-0-526 light weight

Inoperable

machine oil in crank shaft "oil" hole. Apply MIL-

G-25760 general purpose light grease to face of

all gear teeth. Verify ease of cranking. Always

clean and lubricate before packing in transit case

for relocation or storage.

6

Antenna Group

After lowering and disassembly of the antenna,

Damaged or missing components

inspect all components for signs of wear or

damage prior to packing in transit cases.

Replace damaged or worn components as required.

2-8

Previous Page

Previous Page