TM

11-5985-284-15

Section Il. GENERAL SUPPORT TESTING PROCEDURES

pod, 50 inches in height, with a nonmetallic disk

5-3. General

sitting on top. This disk should be calibrated in

a. Testing procedures are prepared for use by

1 markings from 0 to 360 and be attached to

Electronics Field Maintenance Shops and Elec-

a wooden handle (minimum of 36 inches long)

tronic Service Organizations responsible for gen-

which will be used to rotate the disk. The test

eral support maintenance of electronics equipment

antenna should then be mounted on top of the disk

to determine the acceptability of repaired elec-

with provisions made for cable entry and a degree

tronics equipment. These procedures set forth

pointer. The pointer should be alined so that

specific requirements that repaired electronics

when the disk is rotated, the pointer will line up

equipment must meet before it is returned to the

with the degree markings on the disk.

using organization. The testing procedures may

also be used as a guide for the testing of equip-

5-5. Test Conditions

ment that has been repaired at direct support level

if the proper tools and test equipment are

a. All tests shall be conducted in an open field

available.

which is free from all reflective objects.

b. Comply with the instructions preceding each

b. Place Signal Generator AN/USM-44 on the

chart before proceeding to the chart. Perform

ground with a 34-inch vertical antenna connected

each test in sequence. Do not vary the sequence.

directly to the coaxial RF OUTPUT connector

For each step, perform all the actions required

and terminated into a 47-ohm carbon resistor.

in the Test equipment control setting and Equip-

c. The signal generator should be placed on its

ment under test control settings columns; then per-

back to enable the entire length of the antenna to

form each specific test procedure and verify it

extend (34 inches ) above the signal generator top

against its performance standard.

surface.

volt with no modulation at each test frequency.

All test equipment required to perform the test-

e. Place Frequency Meter AN/URM-80 on a

ing procedures given in this section are listed in

table in a position as close as possible to the test

the following chart and are authorized under

TA 11-17, and TA 11-100(11-17).

f. Place Antenna AT-1082/PRC on a tripod

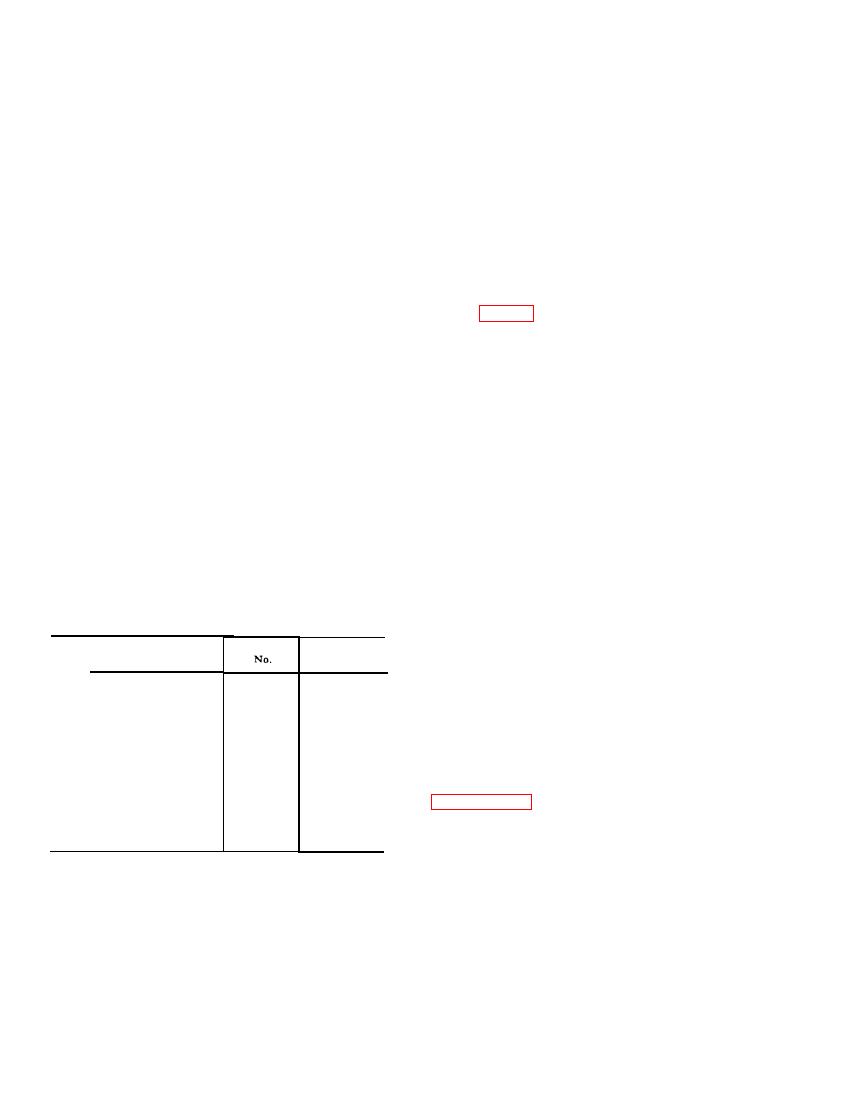

a. Test Equipment.

50 inches high and centered over a 25-foot point

of an imaginary line drawn between the signal

Nomenclature

Federal stock

Technical manual

generator and the AT-1082/PRC under test,

g. Connect the CG-3344/PRC 5-foot coaxial

Signal Generator AN/USM-

6625-669-

TM 11-6625-

cable between the AT-1082/PRC and the fre-

44.

0241

508-10.

quency meter.

Multimeter, ME-26A/U - - - - - -

6625-360-

TM 11-6625-

2493

200-12.

h. A power source of 110 to 120 volts, alternat-

Frequency Meter AN/

6625-649-

TM 11-5095.

ing current ( ac), 60 Hertz (Hz) is required to pro-

URM-80.

4286

vide operating voltages for test equipment listed

Resistor, carbon 47-ohm,

- - - -- - - -

-----------

1/2-watt.

Radio Interference Measur-

6625-776-

TM 11-6625-

ing Set, AN/URM-85.

0595

351-12.

a. Test Equipment and Material. None.

b. Other Equipment Required. To conduct the

b. Test Connections and Conditions. Remove

frequency range test, construct a nonmetallic tri-

cover from case.

Previous Page

Previous Page