TM 32-5985-342-14&P

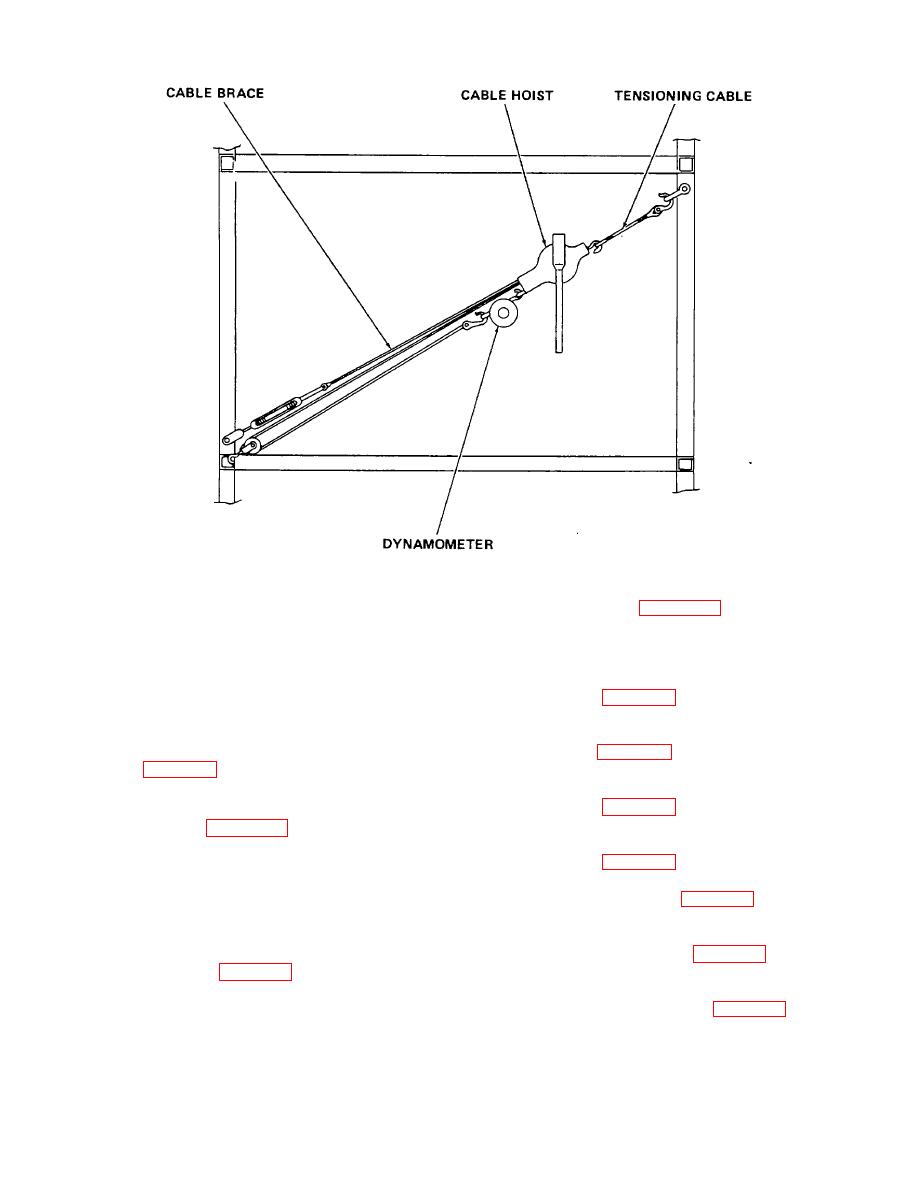

Figure 2-7. Cable Brace Tensioning

(c) Tension each cable at any level

(4) Refer to figure 2-6. Install six grating

incrementally as shown below until 2,500 pounds

angles (18) to braces (19, 11). Secure with 1/2-inch bolt

tension is reached:

(13), hex nut (14), and locknut (15) for each angle.

500 pounds50 pounds

(5) Install grating assembly No.

3 (20).

200-pound increments

Secure with 13 1/4-inch bolts (21), hex nuts (23), and

2,500 pounds final tension

lockwashers (22) (figure 2-6).

(d) After each cable is tensioned, lock

(6) Install grating assembly No.

2 (7).

turnbuckle (33) with wraplock (32) (Detail I, figure 24).

Secure with eight 1/4-inch bolts (21), hex nuts (23), and

lockwashers 22) (figure 2-6).

(8) Torque all fastener hardware to required

values. (See tables 2-3 and 24.)

(7) Install grating assembly No.

1 (24).

e. Final Tower Installation. (See figures 24 and 2-

Secure with six 1/4-inch bolts (21), hex nuts (23), and

lockwashers (22) (figure 2-6).

6.)

(8) Install grating assembly No.

4 (8).

(1) Refer to figure 2-4. Attach a crossover

Secure with eight 1/4-inch bolts (21), hex nuts (23), and

clamp (6) at each pair of cable braces (19). Secure with

lockwashers (22) (figure 2-6).

1/4-inch bolt (7), hex nut (9), and lockwasher (8) for

each clamp.

(9) Install eyenut (25), bevel washer (10),

lockwasher (5), and bolt (26) (figure 2-6).

(2) Install 15 tower steps (30) to tower leg.

Secure with 30 hex nuts (31) (Detail H, figure 24).

(10) Install six track angles (3). Secure with

one 3/8-inch bolt (9), bevel washer (10), lockwasher (5),

(3) Attach ground strap of each cable brace

and hex nut (6) for each angle (figure 2-6).

to tower leg. Secure with 1/4-inch bolts (15), hex nuts

(9), and lockwashers (8) (figure 2-4).

(11) Install horizontal track No. 1 (1). Secure

to threes track angles (3) with three 3/8-inch bolts (4),

lockwashers (5), and hex nuts (6) (figure 2-6).

2-15

Previous Page

Previous Page